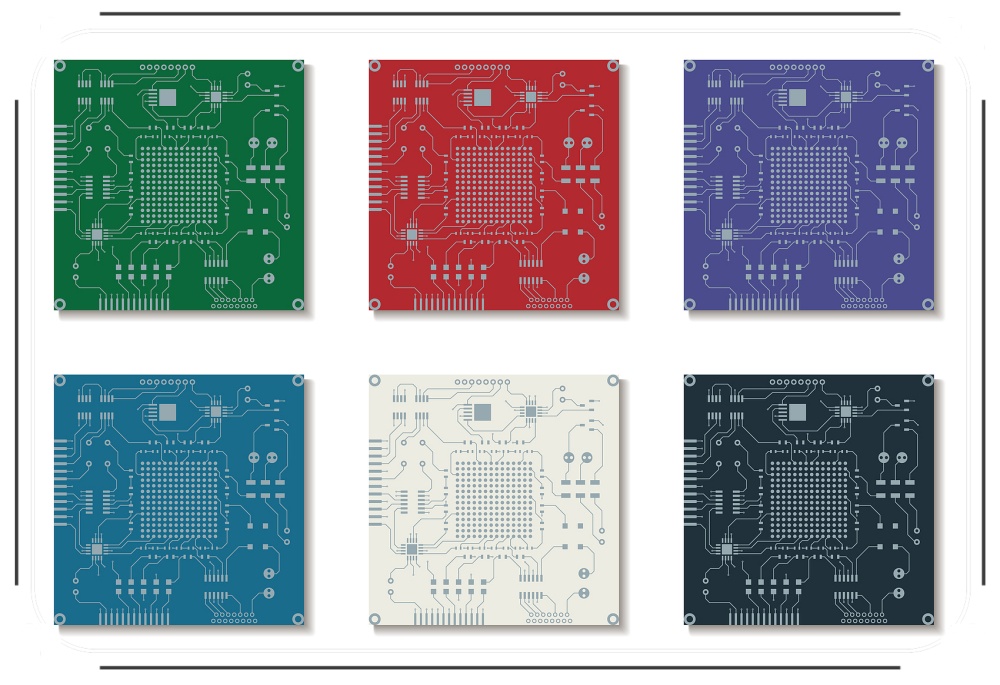

Difference between pcb's with different color soldermasks

There is a significant difference in function, application scenarios and visual effects of PCBs with different color soldermasks. The following is a detailed description of the various colors of soldermask:

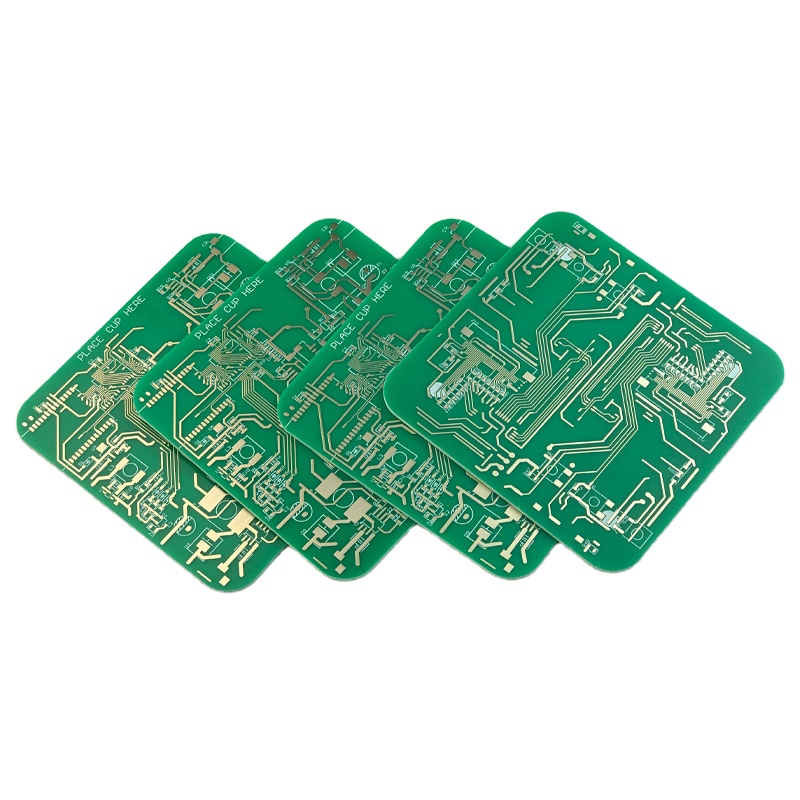

Green Soldermask:

Green is the most common color and is mainly used to protect the circuit board from environmental oxidation and corrosion, to prevent short circuits, and to prevent excessive heat transfer to the board during soldering. The lighter color of green soldermask helps the pads and wiring to be clearly visible for soldering and inspection work.

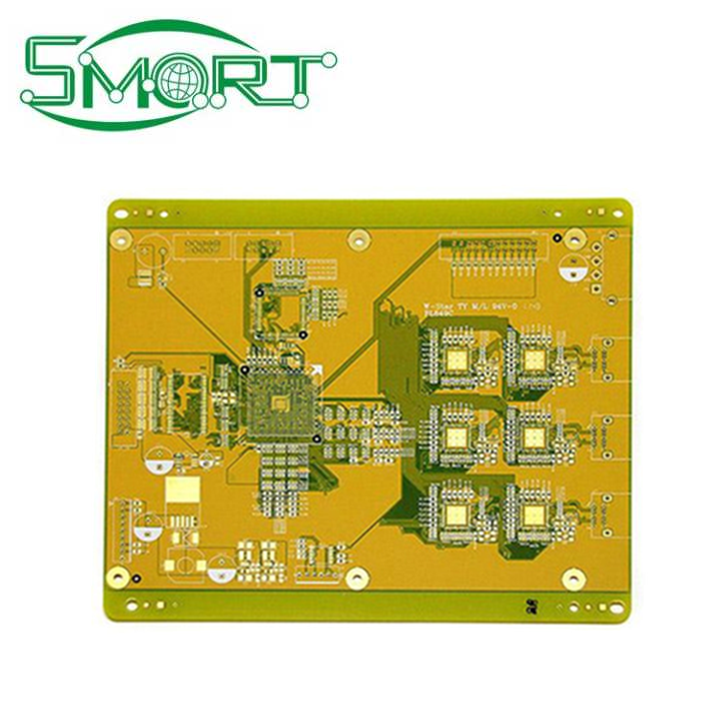

Yellow soldermask:

Yellow soldermask is usually used for the anti-static layer, which can effectively prevent static electricity from interfering with the circuitry and improve the reliability and stability of the circuit board. In addition, yellow soldermask is also commonly used in circuit boards that require gold flash or gold sinking, yellow soldermask can maintain the original color after metallization, suitable for radio equipment.

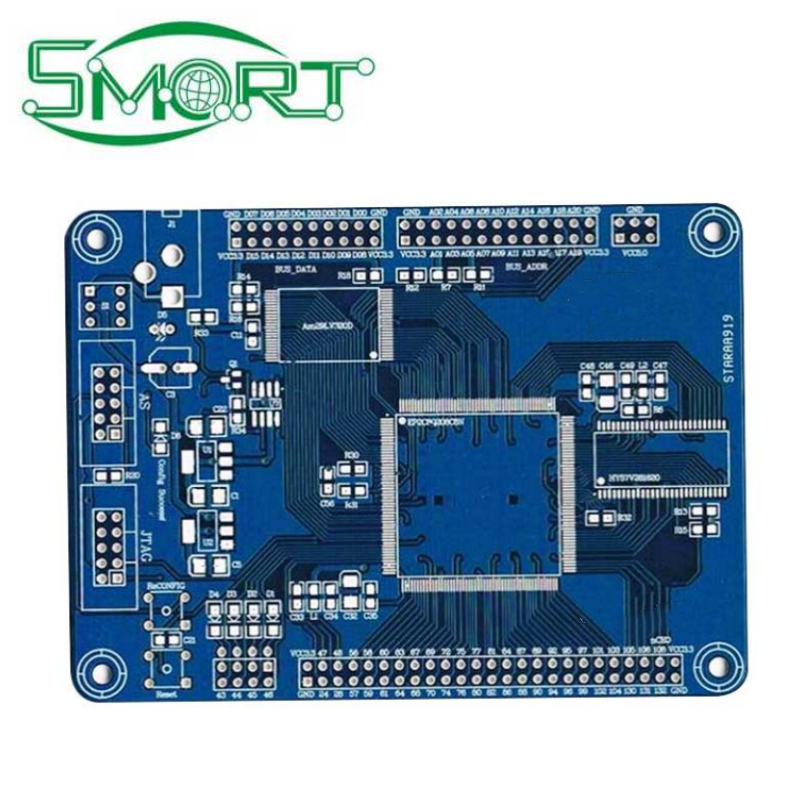

Blue soldermask:

Blue soldermask is suitable for high temperature electronic equipment, such as LED lights. It has high temperature resistance, which prevents thermal expansion and oxidative corrosion of circuits in high-temperature environments and ensures the long-term stability of circuit boards. Blue soldermask also contains a small amount of titanium to improve the reliability of the solder joints, commonly used in high-frequency signal lines.

Red soldermask:

Red soldermask is used in high-end electronic equipment and high-precision circuit boards. It helps detect errors and bad solder joints on circuit boards, and is commonly used for high-precision, complex circuit boards and high-reliability circuit boards. In addition, red soldermask does not contain lead and is more environmentally friendly.

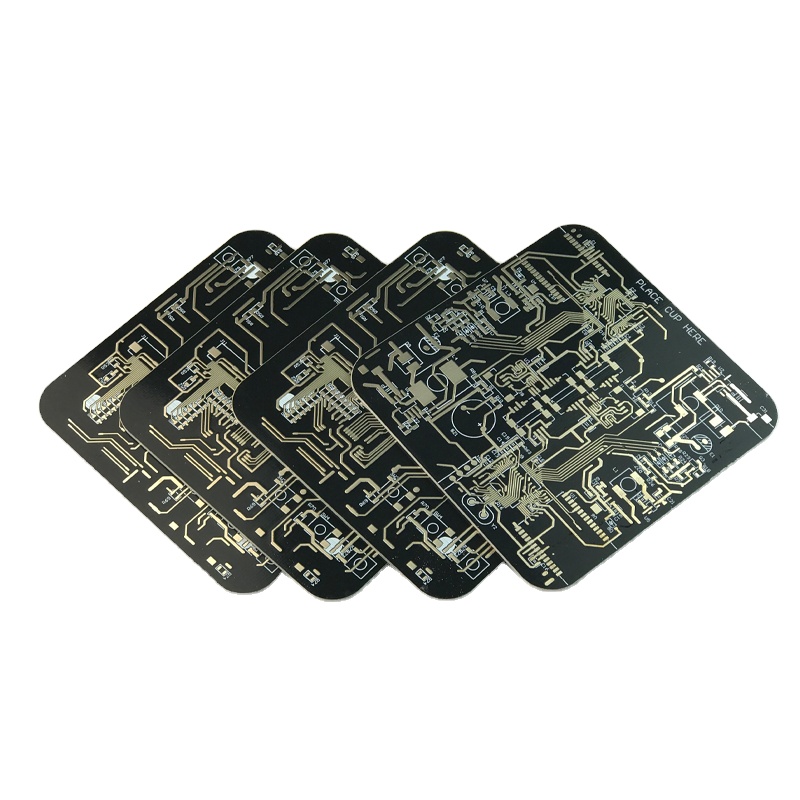

Black and White Soldermask:

Black and white soldermask is mainly used for marking critical components, but black PCBs may create shadows due to light gathering in high temperature applications, which can affect detail tracing. White PCBs contrast well in black screen printing, but it is easy to hide the alignment.

Other color soldermasks:

Such as purple, matte black, matte green, etc. These colors are mostly used in the product classification system, e.g., red may indicate experimental boards, blue indicates key boards, and black indicates boards used for computer internals.

These different colors of soldermask not only affect the appearance and functionality of the PCB, but are also selected based on specific application scenarios and needs.

More information please visit www.smart-bes.com .