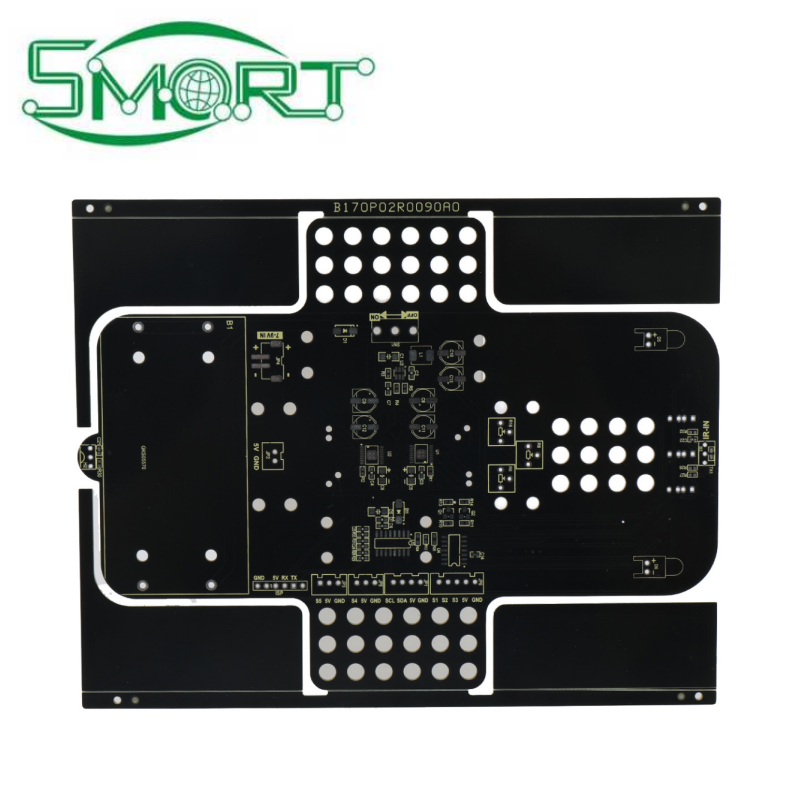

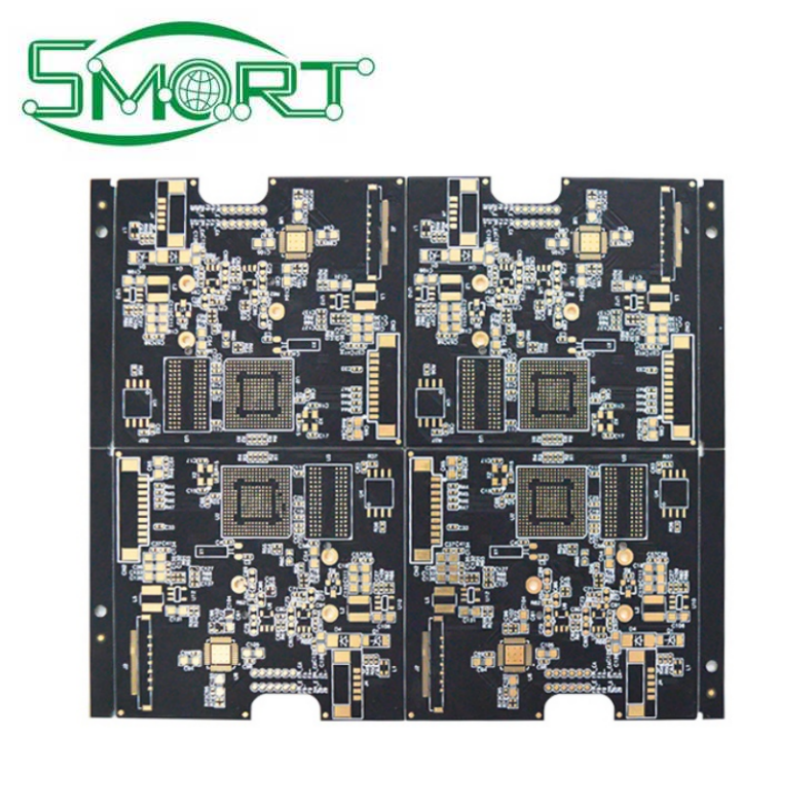

Smart Electronics 4 Layer Black Solder Mask Multilayer Rigid-Flex Circuit Board Prototype And Production PCB

Smart Electronics 4 Layer Black Solder Mask Multilayer Rigid-Flex Circuit Board Prototype And Production PCB

The 4-layer black solder mask Rigid-Flex Board is a highly advanced and versatile printed circuit board (PCB) technology

that combines the rigidity of traditional PCBs with the flexibility of flexible circuits.

This type of board consists of four layers of conductive materials and insulating substrates. The black solder mask provides

several important benefits. Firstly, it offers excellent protection to the underlying circuitry, preventing short circuits and

damage from environmental factors such as moisture, dust, and chemicals. The black color also gives a sleek and professional

appearance to the board.

The rigid-flex design allows for complex geometries and tight packaging requirements. The rigid sections provide stability

and support for components such as integrated circuits, connectors, and other electronic devices. At the same time, the

flexible sections enable the board to bend and conform to the shape of the device or enclosure, saving space and enabling

unique form factors.

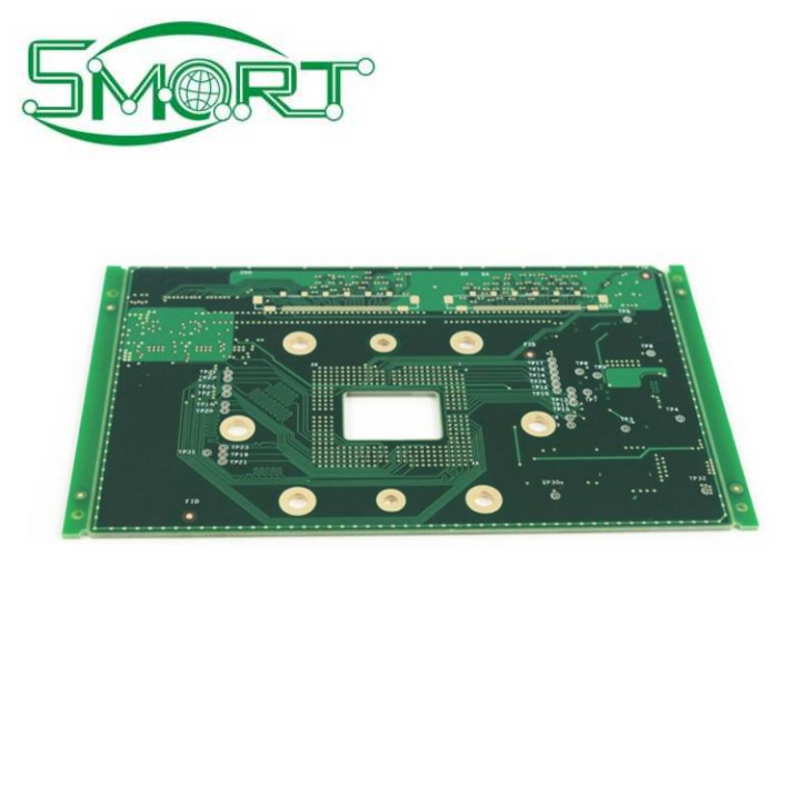

The four layers of the board provide increased routing capacity and signal integrity. Different signal layers can be separated

to minimize interference and crosstalk. Power and ground planes can be incorporated to ensure stable power distribution

and reduce electrical noise.

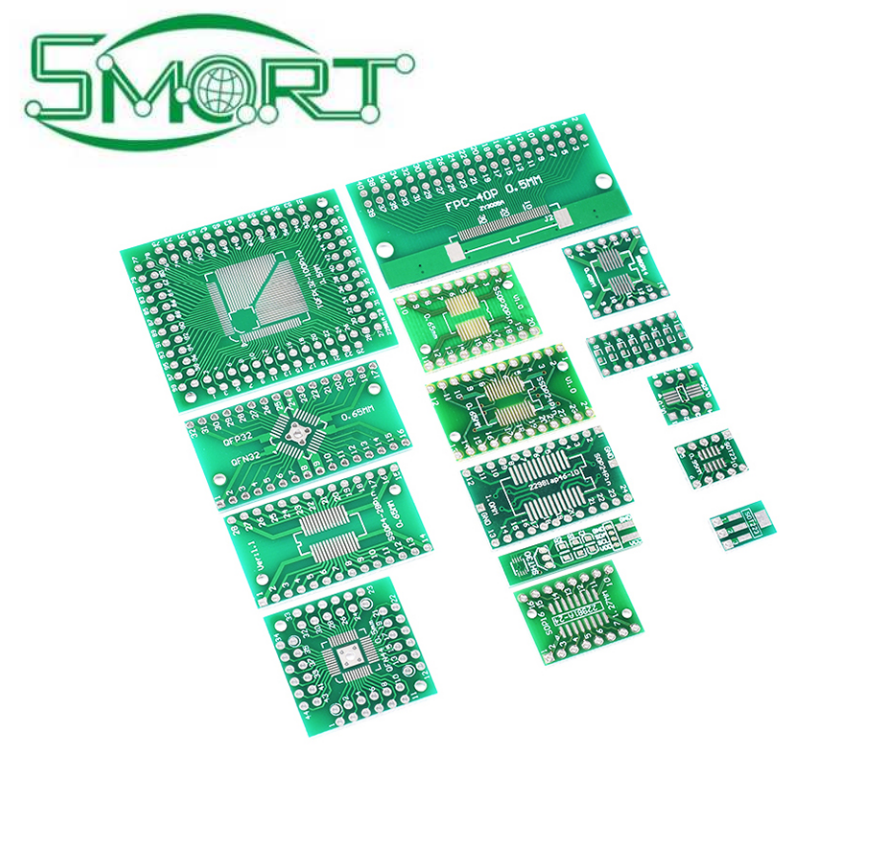

Manufacturing a 4-layer black solder mask Rigid-Flex Board requires advanced technology and expertise. Precise alignment

and lamination of the layers are crucial to ensure reliable performance. Specialized equipment is used for drilling, plating,

and etching to achieve the required accuracy and quality.

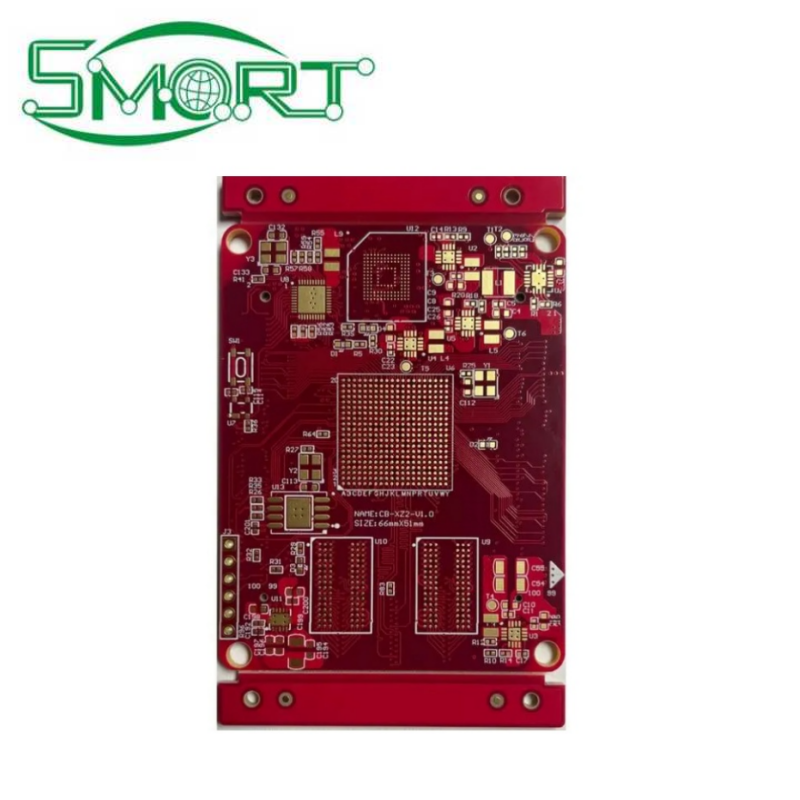

In applications such as aerospace, medical devices, and high-performance electronics, the 4-layer black solder mask

Rigid-Flex Board offers a combination of reliability, flexibility, and functionality that is essential for meeting the demanding

requirements of these industries. It enables designers to create innovative and compact products that are both highly

functional and aesthetically pleasing.